TUBE LASER CUTTING

HIDEAWAY Manufacturing's TRUMPF TruLaser Tube machines provide top-tier tube laser cutting services. Tailored to meet your unique needs, our technology excels in crafting both intricate and robust metal tubes with speed and precision. Discover how we transform metal tubes into high-quality masterpieces.

Ready to elevate your project with our cutting-edge laser technology?

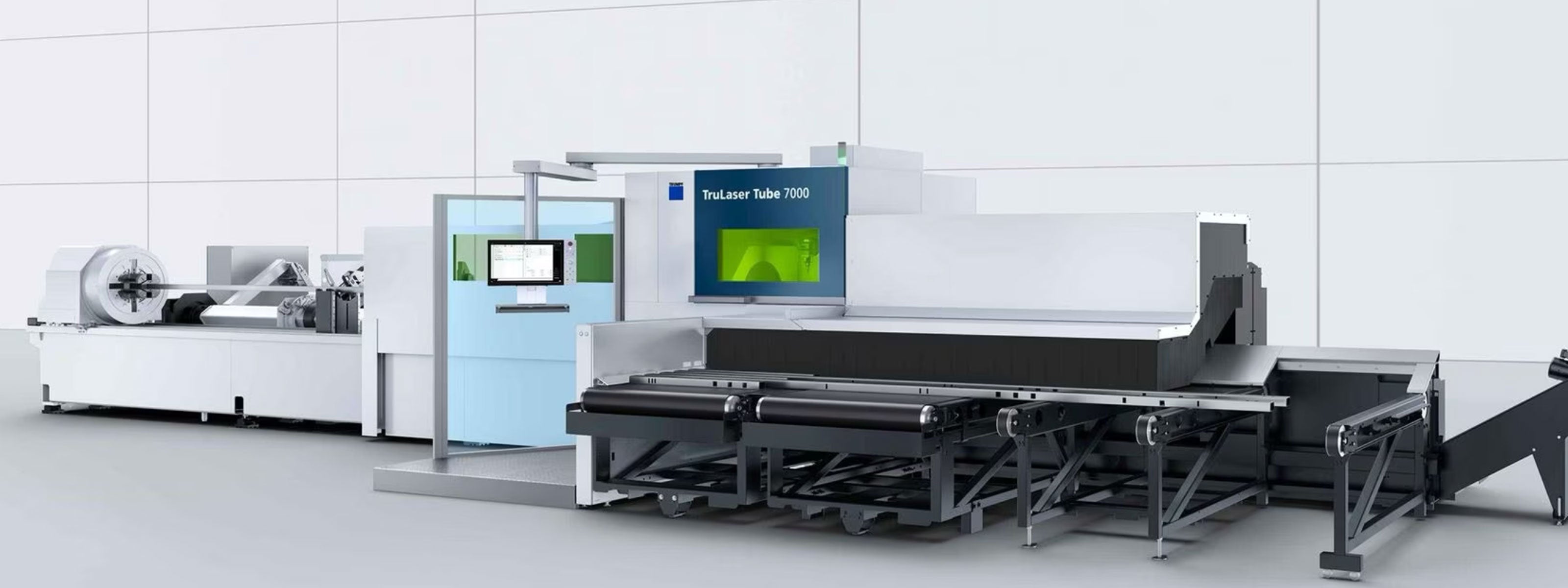

ORDER PARTSTRULASER TUBE 7000 FIBER

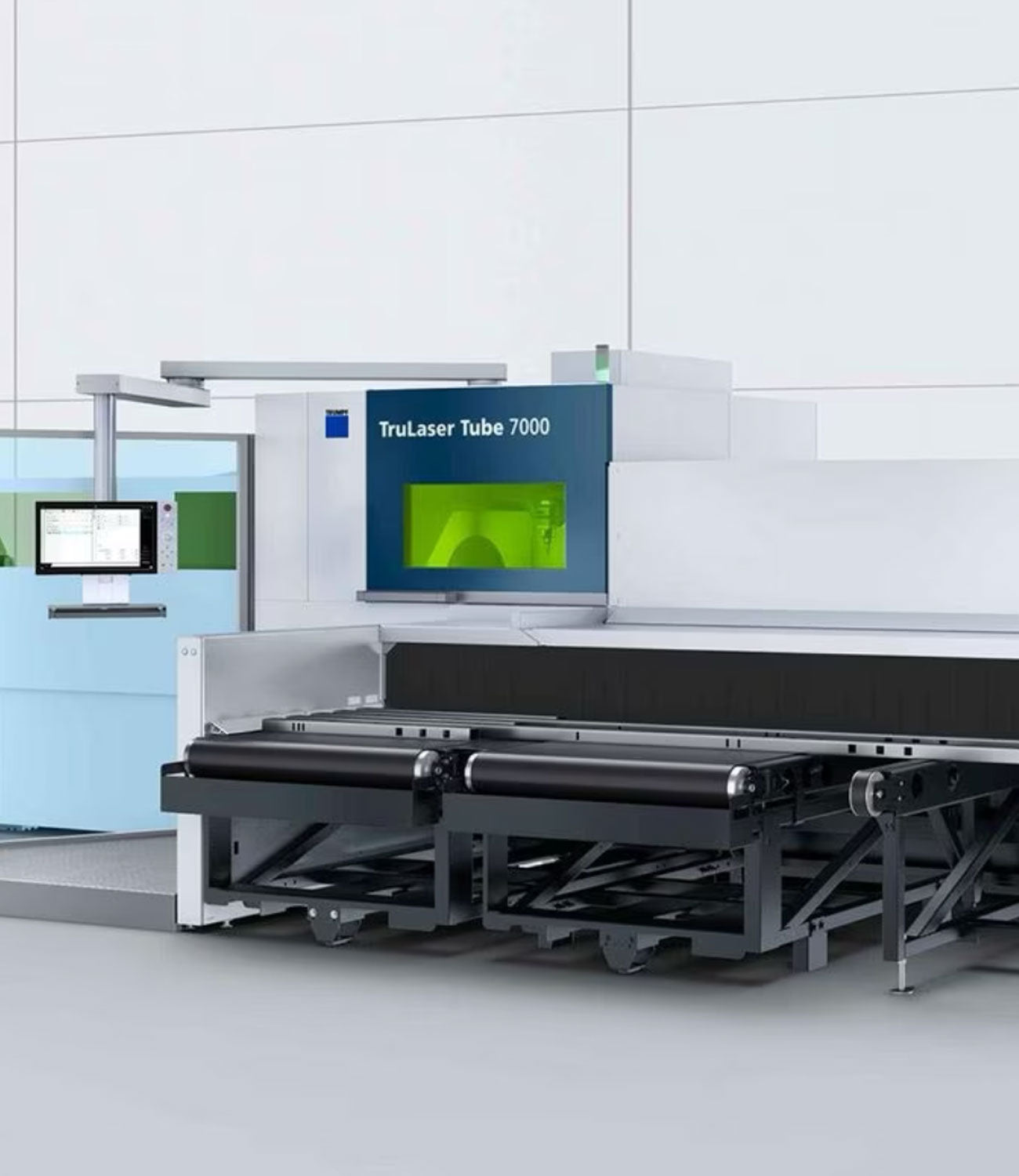

The TruLaser Tube 7000 fiber machine represents the pinnacle of productivity in metal processing. Its solid-state laser offers a broad spectrum of capabilities, excelling in both large-scale and detailed projects. With RapidCut technology, it delivers high-speed, precise cuts, particularly effective in thinner materials. The open design ensures easy loading and unloading, optimizing efficiency for any batch size. Additionally, its integration with the Central Link interface makes it a perfect fit for advanced Industry 4.0 manufacturing environments, enhancing our commitment to innovative and efficient production solutions.

- High-quality bevel cuts of up to 45°

- Process parts with a diameter of up to 10 in. and wall thicknesses of up to 0.625" for mild steel

- Take over further process steps such as tapping threads

- Optimum cutting results

The TruLaser Tube 7000 fiber processes bevel cuts of up to 45 degrees.

With RapidCut, the high feed rates of the solid-state laser come into their own even on smaller contours. This is a significant productivity advantage, particularly in thinner materials.

With the new technology package for tapping, additional machining processes such as flow drilling, tapping, and twist drilling are integrated into the machine. Automation means you can benefit from reduced parts handling and a smaller chance of errors.

FAQ

Use this text to share information about your product or shipping policies.

MAXIMUM RAW MATERIAL LENGTH FOR AUTOMATIC LOADING

FOR LOADMASTER TUBE 6.5 M - 6500 mm

FOR LOADMASTER TUBE 9.2 M - 9200 mm

FOR LOADMASTER TUBE 12.5 M - 12500 mm1

How long will it take to get my orders?

It depends on where you are. Orders processed here will take 5-7 business days to arrive. Overseas deliveries can take anywhere from 7-16 days. Delivery details will be provided in your confirmation email.

Any question?

You can contact us through our contact page! We will be happy to assist you.